|

기계류 지침(Machinery Directive, 2006/42/EC)

유럽으로 들어오는 모든 기계류는 1995년 1월1일부터 아래의 적용 지침을 따라야

한다.적용지침은 초기 89/392/EEC에서 91/368/EEC, 93/44/EEC, 93/68/EEC,

98/37/EC으로 개정되었으며 현재는 European Machinery Directive 2006/42/EC

가 유효하다.

세계 많은 나라들이 기계류와 안전부품에 대해 비강제성 인증을 채택하고 있으나

유럽은 강제안전인증(Mandatory)을 기반으로 하고 있다.

강제안전인증은 기계류 사용으로 인한 수 많은 사고로 인한 사회적 비용 손실을 제품을 안전하게 설계하고 적합하게 설치하며 유지관리를 잘하도록 하여 줄이고 기계를 사용하는 작업자가 적절하게 사용하여 작업자의 안전을 확보하기 위해서 이다.

기계류의 정의

- machinery;

- interchangeable equipment;

- safety components;

- lifting accessories;

- chains, ropes and webbing;

- removable mechanical transmission devices;

- partly completed machinery

기계지침의 규격구분

기계 안전에 관한 유럽 규격은 A규격, B 규격, C 규격으로 나눌수 있다. 제품은 해당되는 모든 3종류의 규격을 충족해야 한다.

- A 규격(EN 414, EN 12100)

기본 안전규격으로 기본 개념, 설계 원칙 및 일반적 측면을 규정하는 규격이다.

- B 규격( EN 13850, EN 13849-1, EN 60204-1 등)

일반적인 기계의 용도 및 목적에 따라 광범위하게 구분된 기계에 적용되는 안전에 관계되는 규격

1) B1규격은 특정 안전 측면에 관한 규격(전기, 안전거리, 표면온도, 소음 등)

2) B2규격은 안전관련 장치 와 기계부품 등에 관한 규격(비상스위치, 압력감지장치 등)

- C 규격

특정 기계 또는 기계 그룹에 관한 상세한 안전 요구사항을 규정하는 규격

필수준비문서

- 매뉴얼:사용자매뉴얼, 서비스매뉴얼 (전문가용)

- Parts List (승인부품의 인증서 사본:CoC , AoC , DoC , Type approval Certificates)

- Catalogues :완제품 및 주요부품류

- 도면:제품 , 조립도 , 주요부 조립도

- 유압, 공압, 전기 관련 자료

※ 아래의 기계들은 인증기관의 인증을 꼭 받아야 CE 마킹이 가능한 제품들이다.(ANNEX IV)

- Circular saws (single- or multi-blade) for working with wood and material with similar physical characteristics or for working with meat and material with similar physical characteristics, of the following types:

- sawing machinery with fixed blade(s) during cutting, having a fixed bed or support with manual feed of the workpiece or with a demountable power feed;

- sawing machinery with fixed blade(s) during cutting, having a manually operated reciprocating saw-bench or carriage;

- sawing machinery with fixed blade(s) during cutting, having a built-in mechanical feed device for the workpieces, with manual loading and/or unloading;

- sawing machinery with movable blade(s) during cutting, having mechanical movement of the blade, with manual loading and/or unloading.

- Hand-fed surface planing machinery for woodworking.

- Thicknessers for one-side dressing having a built-in mechanical feed device, with manual loading and/or unloading for woodworking.

- Band-saws with manual loading and/or unloading for working with wood and material with similar physical characteristics or for working with meat and material with similar physical characteristics, of the following types:

- sawing machinery with fixed blade(s) during cutting, having a fixed or reciprocating-movement bed or support for the workpiece;

- sawing machinery with blade(s) assembled on a carriage with reciprocating motion.

- Combined machinery of the types referred to in points 1 to 4 and in point 7 for working with wood and material with similar physical characteristics.

- Hand-fed tenoning machinery with several tool holders for woodworking.

- Hand-fed vertical spindle moulding machinery for working with wood and material with similar physical characteristics.

- Portable chainsaws for woodworking.

- Presses, including press-brakes, for the cold working of metals, with manual loading and/or unloading, whose movable working parts may have a travel exceeding 6 mm and a speed exceeding 30 mm/s.

- Injection or compression plastics-moulding machinery with manual loading or unloading.

- Injection or compression rubber-moulding machinery with manual loading or unloading.

- Machinery for underground working of the following types:

- locomotives and brake-vans;

- hydraulic-powered roof supports.

- Manually loaded trucks for the collection of household refuse incorporating a compression mechanism.

- Removable mechanical transmission devices including their guards.

- Guards for removable mechanical transmission devices.

- Vehicle servicing lifts.

- Devices for the lifting of persons or of persons and goods involving a hazard of falling from a vertical height of more than three metres.

- Portable cartridge-operated fixing and other impact machinery.

- Protective devices designed to detect the presence of persons.

- Power-operated interlocking movable guards designed to be used as safeguards in machinery referred to in points 9, 10 and 11.

- Logic units to ensure safety functions.

- Roll-over protective structures (ROPS).

- Falling-object protective structures (FOPS).

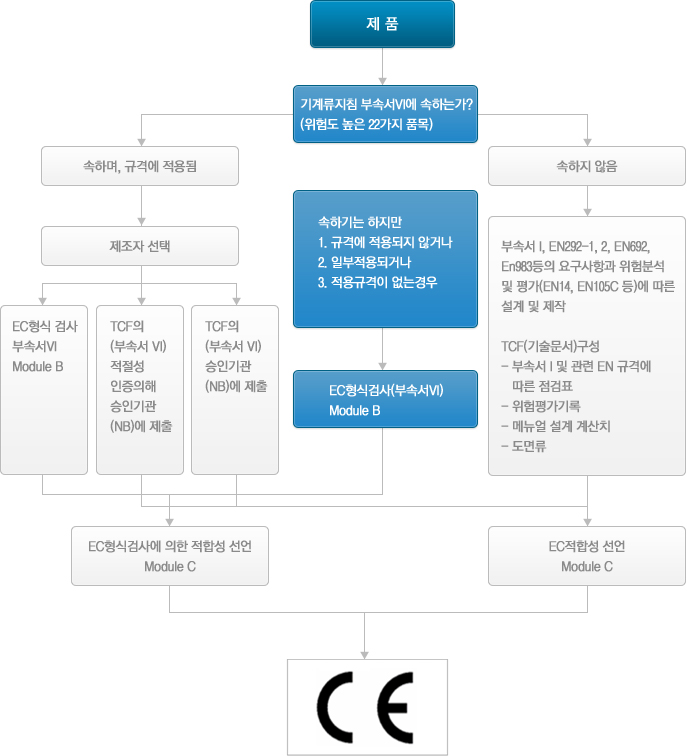

기계류지침(2006/42/EC)에 따른 적합성 절차

|

|